Performance Characteristics

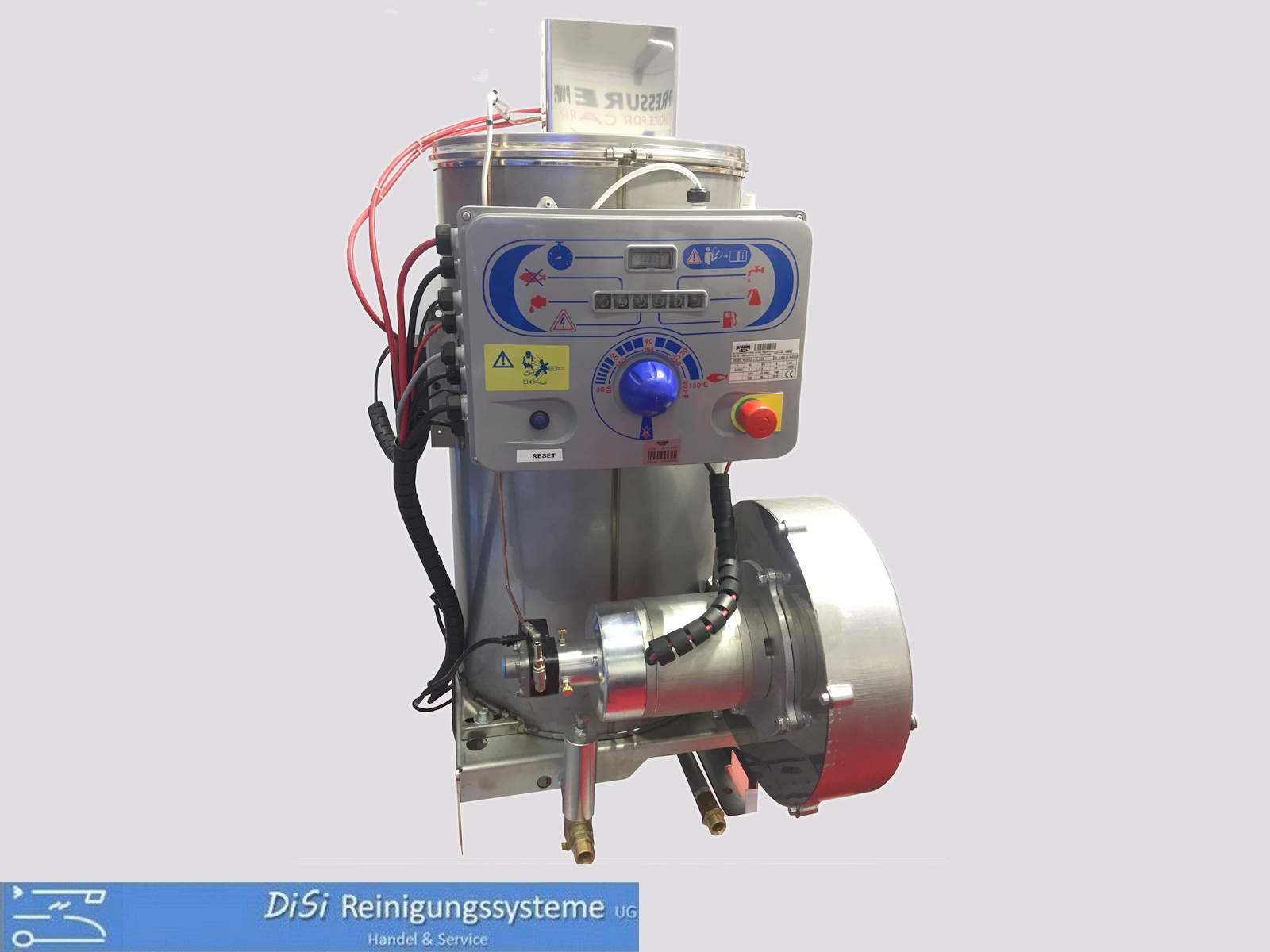

The ready-to-connect mobile HOTBOX from Mazzoni is modularly connected to your cold water high-pressure cleaner with a short high-pressure hose section and enables the water to be heated up to 150 degrees like a hot water high-pressure cleaner. The original hose package of your high-pressure cleaner is then connected to the hotbox (all adapters suitable for your system are included in the scope of delivery).

The hotbox has an oil/diesel burner, built-in diesel tank, low water protection, flow monitor, optical flame monitoring, pressure relief valve and thermostat, on which you can set the desired temperature.

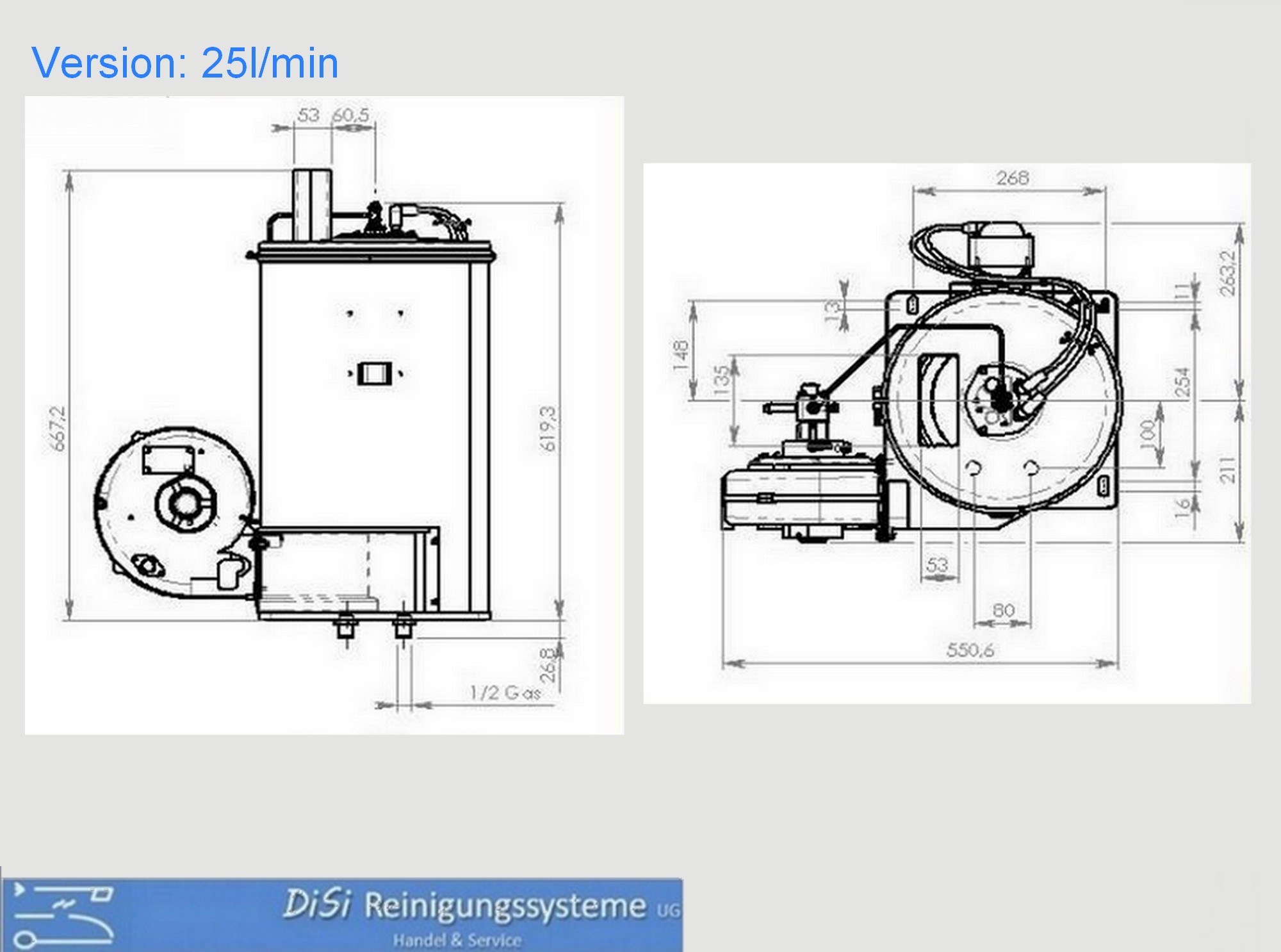

The hotbox has a burner output of 105KW with a maximum flow rate of 25l/min. This dimensioning corresponds to a ΔT = 85 ° C.

1. At z. B. 25l / min and an inlet temperature of 10 ° C, the hotbox reaches an outlet temperature of 65 ° C.

2. At z. B. 15l / min and an inlet temperature of 10°C, the hotbox reaches an outlet temperature of 95°C. This model includes the entire chassis, carriage and fairing as shown in the first picture.

The Mazzoni company has existed in Northern Italy since 1969 as a manufacturer of high-pressure cleaners, steam jets and individual components such as burners, high-pressure crankshaft pumps and attachments. The owner-managed family company with around 80 employees continues to produce everything by hand and only supplies top-quality components and devices in a rock-solid design for continuous industrial operation. The focus here is on quality, not profitability. The supply of spare parts and / or maintenance is guaranteed by our workshop in 65205 Wiesbaden, other dealers and German-speaking contacts at Mazzoni.

THE 3-STAGE PROCEDURE OF PROFESSIONAL / COMMERCIAL FACADE CLEANING:

Due to the nowadays mandatory insulation of the plaster facades, after some time they start to form externally organic deposits such as algae, fungi, spores and lichens.

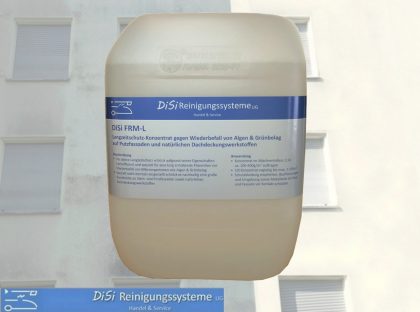

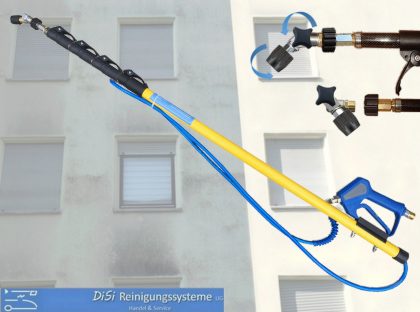

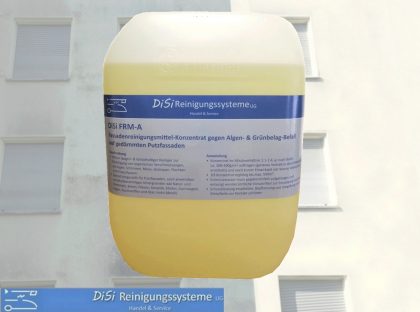

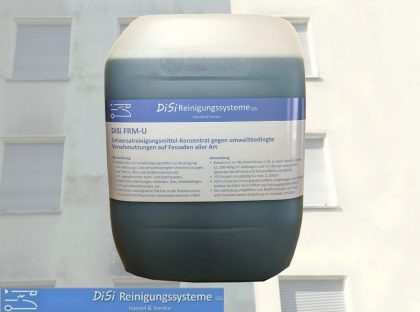

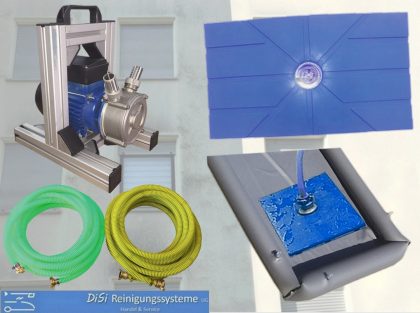

1. First of all, the waste water collecting tray is laid out with air rims below the facade to be cleaned in order to collect the waste water that occurs. Then the cleaning agent DiSi-FRM-A or DiSi-FRM-U is applied using our low-pressure chemical pressure pump and low-pressure chemical CARBON telescopic lance using the low-pressure method <40Bar. Most of the dirty water runs off the facade, collects in the dirty water collecting tray and is sucked into a canister by our chemical suction pump or flat suction mat (subject to disposal).

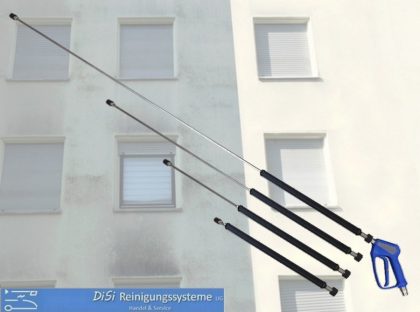

2. Then, after a short exposure time, the facade is washed off using the chemical pressure pump in HD operation or a more powerful high-pressure cleaner and the HP CARBON telescopic lance (9.5m or 14m). Here the 180Bar (14m TL) on the HP nozzle are only necessary to allow the telescopic lance to “fly” through the counter pressure at the cranked end of the lance. At a distance of just 1m from the facade, only about 30bars arrive directly on the facade to wash off the remnants of the loosened dirt. This dirty water is also collected and pumped out (subject to disposal).

3. Finally, it is best to apply the long-term protection DiSi-FRM-L again with the chemical pressure pump and chemical CARBON telescopic lance (9.5m).

Since cleaning agents containing surfactants and lye have a very corrosive effect on metallic components, all cleaning components, down to the smallest screw connection, that come into contact with these cleaning agents and also the dirty water, must be made of SS stainless steel and thus permanently acid and lye-resistant.

Please observe the legal regulations for all cleaning agents.